Highly qualified team collaboration to actively and efficiently manage the entire product cycle for customers

Rigorous manufacturing processes bring high-quality products

Advanced technology and equipment meet the constantly upgrading requirements of customers

Agile supply chain management achieves immediate and flexible customer needs

A globalized operations team helps customers achieve seamless transition between domestic and international businesses

A team of excellent engineers with 30 years of rich design experience, meticulously dedicated to the independent research and development and functional certification of various cutting-edge intelligent devices, possessing numerous independently innovative products and patents. Long term cooperation with Fortune 500 companies such as Nokia and Alstom, participating in collaborative research and development.

We have a comprehensive New Product Introduction (NPI) management system and quality monitoring system, as well as multiple testing capabilities. We can provide customers with services such as first article functional certification, sample production testing, and small batch production verification. Not only does it have end-to-end production capabilities with complete supporting facilities, but it can also accept small batch production from customers and provide DFM recommendations.

Having advanced design software, we can provide fast solutions according to customer design requirements.

Familiar with the manufacturing process of various cabinets, provide customer design optimization suggestions for the processing characteristics and technical difficulties of each process.

Has a certain predictive ability for errors and technical bottlenecks that are prone to occur in the processing of different types of products, and can detect and handle unexpected situations in the product processing process in a timely manner.

Wagner's fast color changing spray booth can improve powder loading rate and enhance spray production efficiency.

The world's advanced LVD bending equipment can basically meet the processing needs of various parts, ensuring efficient production of parts.

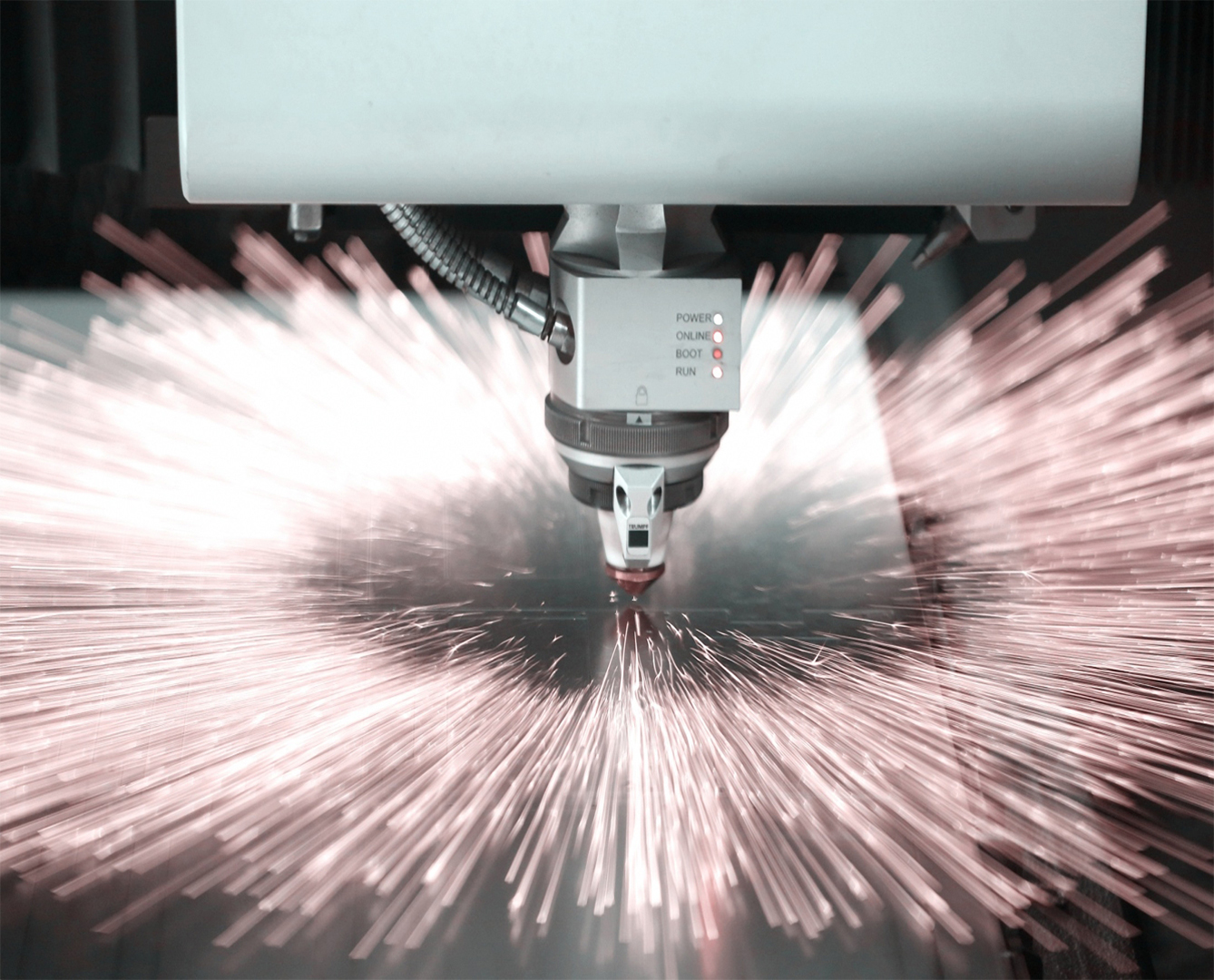

TRUMPF CNC punching machines and laser cutting machines have high production efficiency and excellent processing performance.

Advanced VQC equipment can quickly detect the dimensions produced and make precise comparisons with drawings.

Provide PCBA welding assembly, structural testing, functional testing, system integration, board diagnosis and maintenance services to customers.

In addition to welding, assembly, testing and other equipment at all levels, there are currently three surface mount production lines, all equipped with high-precision screen printing, SMT, reflow furnace, as well as quality monitoring equipment such as SPI and AOI after furnace. Provide flexible, convenient, high-quality, and cost-effective OEM services to meet the production needs of different customers.

Equipped with various advanced high-precision and high-density crimping modes, it can efficiently, quickly, and completely meet the production requirements of customer backboards.

Equipped with FCI automatic press, domestic 5-ton pneumatic large press, domestic manual large table press, MCP-6T high-precision servo press, Belgian ASPIM automatic needle insertion machine and other equipment.

Capable of producing large-sized backboards, designing and manufacturing crimping molds, and crimping pads independently.

Using specialized testing fixtures and flying needle testing equipment, equipped with connector on/off testing capabilities.

Capable of RF terminal network analysis and testing.

Having meticulous and comprehensive equipment integration capabilities, including independent production, assembly, chip burning and testing of backboards, shelves, modules, and cables, ultimately summarizing for system integration assembly, overall testing, inspection, packaging, and delivery. Each process allocates materials according to SOP and implements full process control from assembly to functional testing, accompanied by SOP electronic visualization to guide each operational step. Implement MES information tracking and control throughout the entire process.

Capable of supporting testing for integrated circuit boards and overall cabinet systems, providing a complete set of testing and quality assurance services. We can provide various special testing contents: IP waterproof testing, heat exchange testing, high-temperature aging testing, safety testing, salt spray testing, etc. We can also accept customized testing services from customers.

We have a comprehensive global supply chain management system, covering supply chain risk control, quality management, overall supply chain migration, and cross-border supply chain management. Committed to providing customers with complete and efficient supply chain management services.